Do you know the common misunderstanding of ultrasonic welding machine?

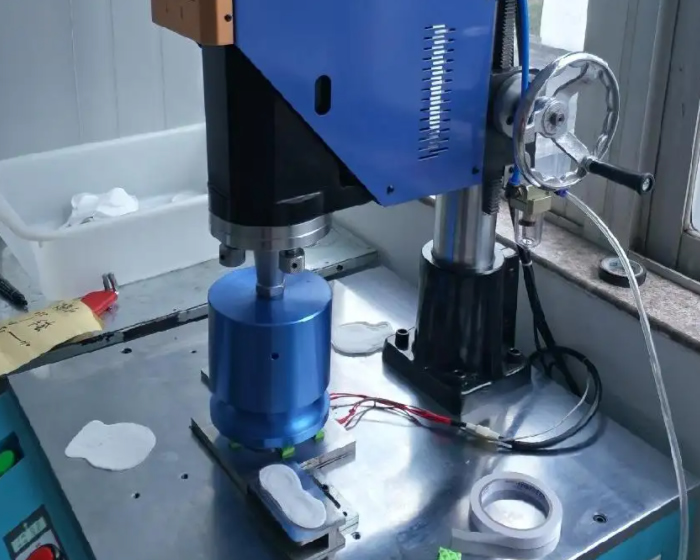

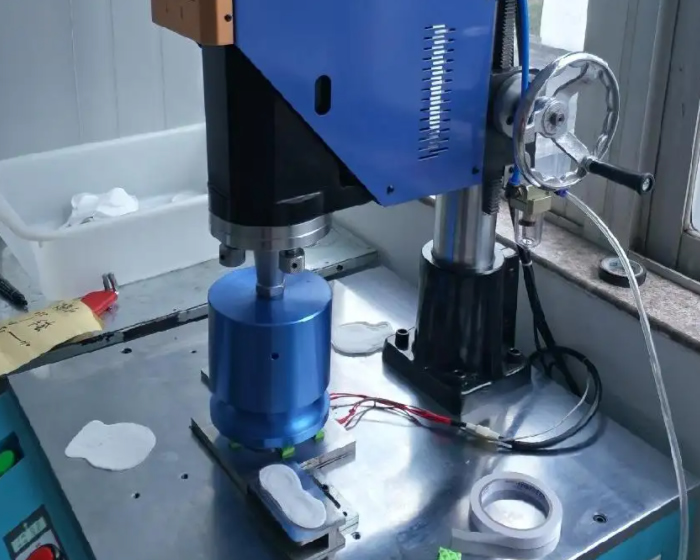

At present, ultrasonic welding machines are widely used, and product packaging, cutting, riveting, embossing, punching and other industries are indispensable equipment. Therefore, various ultrasonic welding machines with different functions have emerged as the times require.

Different application fields, application methods and equipment requirements are very different. There is a wide gap in current use among consumers. Let's explain these misunderstandings!

Misunderstanding of ultrasonic output power; The size of ultrasonic output power is determined by the diameter and thickness of piezoelectric ceramic chips, materials and design technology. Once the sensor is complete, the power supply is complete. Measuring the output energy is a complex process.

This does not mean that the larger the sensor, the more power transistors used in the circuit, and the greater the energy output. It requires a very complex amplitude measuring instrument to measure its amplitude. Because most users know too much about ultrasound, some sales personnel mislead consumers.

The electric energy consumed does not reflect the output ultrasonic power. For example, low longitudinal energy and high current consumption can only indicate that the equipment has low efficiency and high reactive power is appropriate.

Misunderstanding of ultrasonic welding machine selection: factors to be considered in the use of output power, oscillation frequency and amplitude range, such as material workpiece, area of welding wire, whether there are electronic components in the workpiece, are sealed. Misunderstandings The greater the power, the better. This is also a misunderstanding.

If you do not know much about ultrasonic, please consult the engineering technicians of the regular ultrasonic manufacturer. If possible, go to the manufacturer for on-site communication, and do not blindly follow the misleading of some informal ultrasonic salespersons.

At present, the enterprises that produce relevant equipment are particularly mixed, mostly family workshops, mechanical analog circuits, and do not understand the working principle.

The imitated equipment has the following fatal defects: first, the quality of purchased raw materials cannot be guaranteed, and second, the core technology of the production process is not mastered. The equipment often shows instability when working at medium and high power, and the product qualification rate is low. Sometimes the equipment will be damaged.

Your location:

Your location:

Tel.: 0755-27163020

Tel.: 0755-27163020 Mobile:15989539998 Mr.Su

Mobile:15989539998 Mr.Su Email: szmaijin@163.com

Email: szmaijin@163.com Website: www.maijinkeji.net

Website: www.maijinkeji.net Address: 3F, Building 5, Huixin Intelligent Industrial Park, Xinhu Street, Guangming District, Shenzhen

Address: 3F, Building 5, Huixin Intelligent Industrial Park, Xinhu Street, Guangming District, Shenzhen

Website

Website