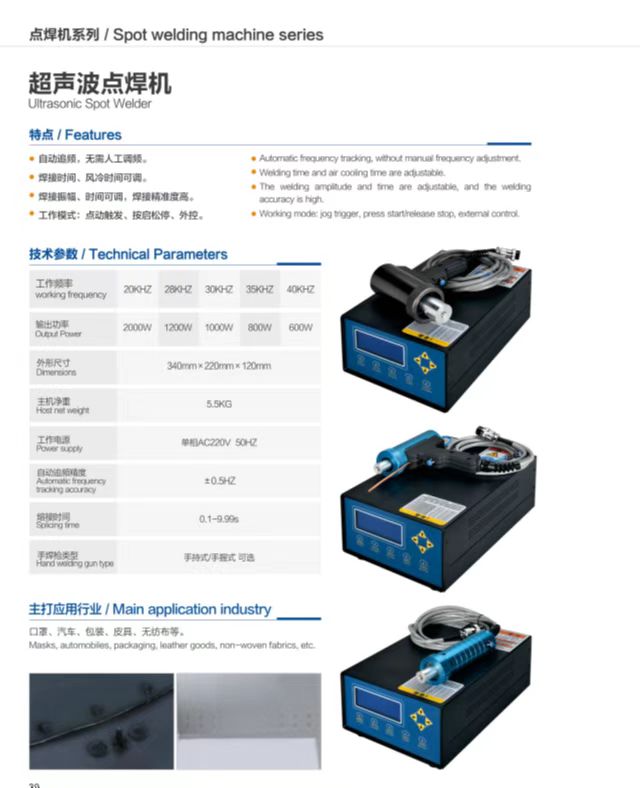

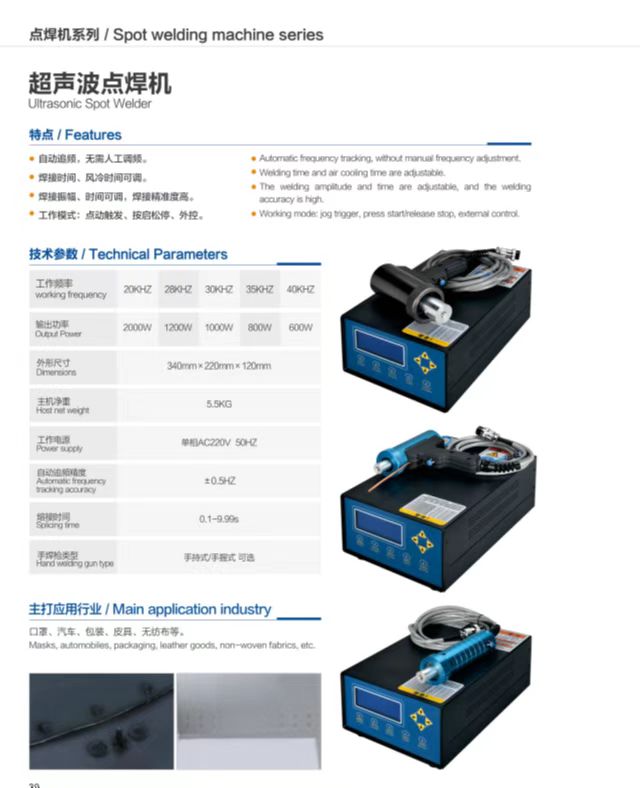

Features of ultrasonic plastic spot welding machine:

1. Small size, simple operation and fast cleaning; Adopt modular integrated circuit, with strong power output;

2. Built-in full-automatic protection circuit ensures safe use and stable and reliable operation. The welding surface is firm, high strength, beautiful and environmentally friendly.

3. Different ultrasonic welding heads can be replaced according to the size of rivet point and welding requirements of the products to be welded, which is fast and convenient.

Principle of ultrasonic plastic spot welding machine:

Ultrasonic plastic spot welding machine converts 50/60HZ current into high-frequency alternating current through ultrasonic generator, and inputs the electric energy into ultrasonic transducer to generate mechanical movement of the same frequency. The mechanical motion is transmitted to the ultrasonic welding head through the amplitude modulator device, and the welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, energy is converted into heat energy through friction, melting the plastic. The short pressure maintained on the workpiece after the vibration stops causes the two weldments to solidify in a molecular link manner. Generally, the welding time is less than 1 second, and the welding strength obtained can be comparable to that of the body.

Your location:

Your location:

手持点焊机

手持点焊机

Tel.: 0755-27163020

Tel.: 0755-27163020 Mobile:15989539998 Mr.Su

Mobile:15989539998 Mr.Su Email: szmaijin@163.com

Email: szmaijin@163.com Website: www.maijinkeji.net

Website: www.maijinkeji.net Address: 3F, Building 5, Huixin Intelligent Industrial Park, Xinhu Street, Guangming District, Shenzhen

Address: 3F, Building 5, Huixin Intelligent Industrial Park, Xinhu Street, Guangming District, Shenzhen

Website

Website